Innovations in Aluminum Castings: advancements that improve quality and efficiency

Wiki Article

Recognizing the Role of Aluminum Foundry in Creating High-Quality Steel Products

Aluminum shops are crucial in the production of premium metal items. They utilize numerous casting strategies, such as sand and die spreading, to accomplish accuracy and sturdiness. With rigorous quality assurance procedures in location, these facilities ensure that their items meet market standards. As markets advance, the role of Aluminum factories continues to adjust. This questions concerning future advancements and sustainability methods that might redefine their impact.The Aluminum Spreading Process: Technologies and strategies

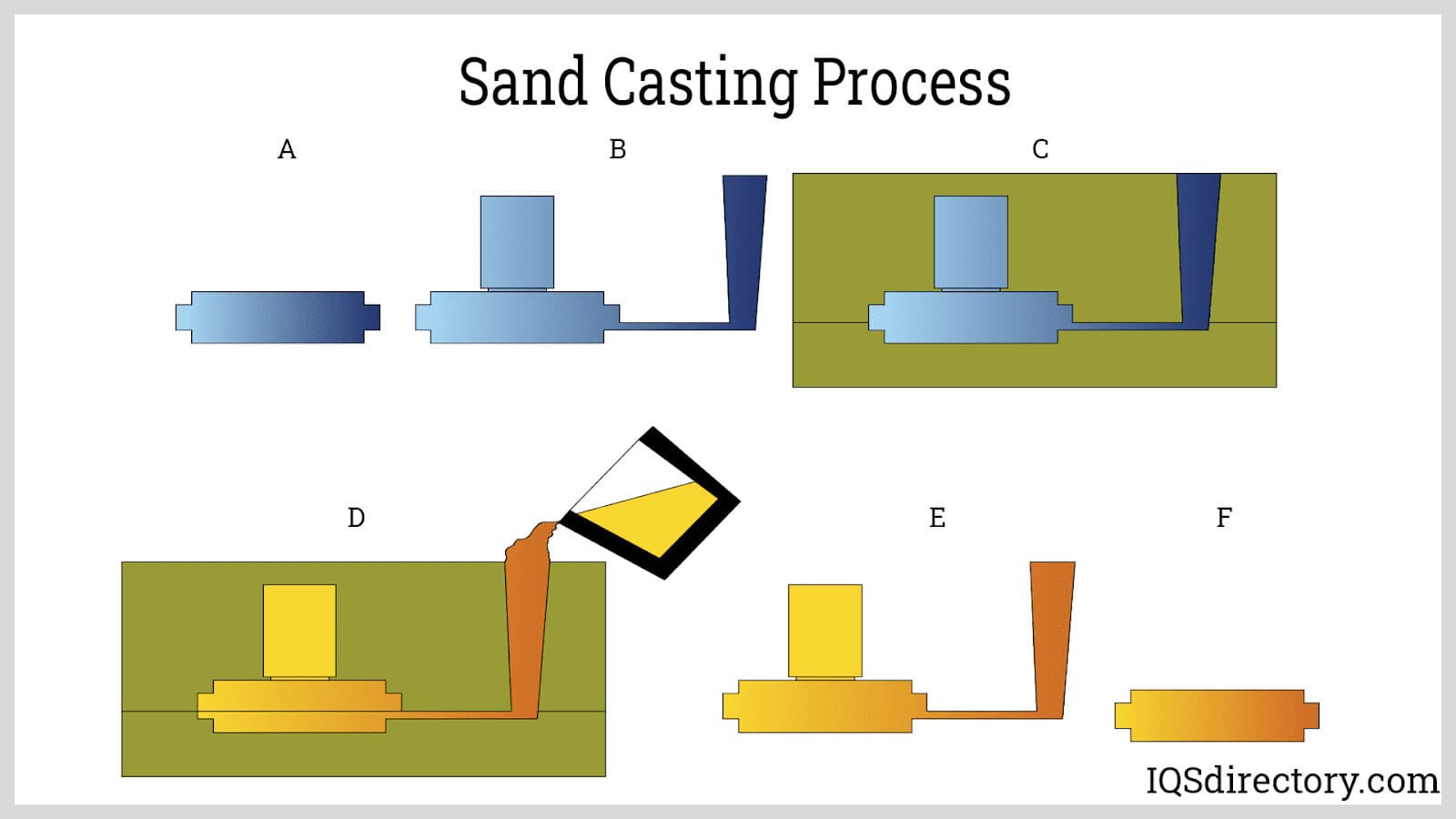

The Aluminum casting process has developed substantially, including different strategies and innovations that enhance efficiency and item top quality. Typically, methods such as sand spreading and die casting were predominant; however, improvements have presented procedures like financial investment spreading and low-pressure die spreading. These technologies make it possible for suppliers to achieve intricate layouts and tighter tolerances, minimizing product waste and boosting general performance.Additionally, the integration of computer-aided layout (CAD) and simulation software enables for even more accurate modeling and testing, guaranteeing that potential problems are recognized early in the manufacturing cycle. Additionally, developments in alloy formulas bring about improved mechanical residential or commercial properties and rust resistance

These developments not only improve production yet additionally advertise sustainability by decreasing energy consumption and exhausts. As the market remains to accept brand-new innovations, the Aluminum spreading process continues to be a critical part in creating high-grade metal products that fulfill varied market needs.

Applications of Aluminum in Numerous Industries

Light weight aluminum's versatility and favorable residential properties make it an important product throughout different markets. In the automotive market, Aluminum is commonly made use of for its lightweight features, adding to boosted fuel efficiency and performance. The aerospace sector likewise advantages, as aluminum's high strength-to-weight proportion enhances airplane style while preserving security standards.In construction, Aluminum is favored for its toughness and resistance to deterioration, making it ideal for window frames, roof covering, and architectural parts. The product packaging industry leverages aluminum's non-toxic nature and recyclability, especially in food and drink containers, guaranteeing security and sustainability.

In addition, the electric market employs Aluminum for its superb conductivity in circuitry and transmission lines. The customer items sector utilizes Aluminum in items varying from kitchen utensils to electronics, emphasizing its versatility. Subsequently, Aluminum plays an essential function in boosting performance, effectiveness, and sustainability throughout diverse applications.

Advantages of Using Aluminum Over Various Other Metals

While lots of metals are utilized in different applications, Aluminum stands apart due to its one-of-a-kind combination of homes that provide several benefits over various other materials. Its light-weight nature greatly minimizes transportation expenses and power intake, making it perfect for sectors such as automobile and aerospace. Light weight aluminum's exceptional deterioration resistance improves longevity, prolonging the life of products and minimizing upkeep requirements. Additionally, it displays high thermal and electrical conductivity, making it appropriate for electrical and thermal monitoring applications.The steel's pliability enables complex forms and elaborate designs, giving adaptability in making processes. Additionally, Aluminum is 100% recyclable without loss of quality, advertising sustainability you could try these out and minimizing environmental impact. Aluminum Foundry. These qualities, incorporated with its reasonably inexpensive contrasted to other steels, setting Aluminum as a preferred selection throughout numerous industries. On the whole, the advantages of Aluminum add to its boosting popularity in the production of high-quality steel products

Quality Assurance Measures in Aluminum Foundries

Quality assurance procedures play a necessary duty in the Aluminum Foundry process, making sure that the end products satisfy extensive industry criteria and consumer expectations. These steps normally begin with material examination, where raw Aluminum is evaluated for pureness and composition. Once the casting process starts, temperature level control is crucial; maintaining optimal molten metal temperatures protects against issues such as porosity and contraction.In addition, non-destructive screening (NDT) methods, including radiographic and ultrasonic assessments, are utilized to identify interior defects without damaging the spreadings. Aesthetic assessments are likewise performed at different stages to identify surface area flaws.

Adherence to recognized top quality monitoring systems, such as ISO requirements, is vital for maintaining uniformity and traceability throughout the manufacturing process. Regular audits and staff member training on top quality criteria add to a total culture of excellence, ensuring that the products not only satisfy however surpass customer expectations in performance and resilience.

The Future of Aluminum Foundries: Trends and Sustainability

As the Aluminum Foundry market progresses, arising patterns and an emphasis on sustainability are improving its landscape. Enhancing demand for light-weight and resilient materials in sectors like vehicle and aerospace drives technology in Aluminum spreading techniques. Advanced modern technologies, such as expert system and automation, are enhancing production effectiveness and accuracy while reducing waste.Sustainability is ending up being an extremely important problem, triggering foundries to execute environmentally friendly practices, consisting of recycling Aluminum scrap and utilizing renewable resource sources. The shift towards circular economic situation principles motivates click site shops to reduce ecological impact while satisfying customer assumptions for sustainable items.

In addition, regulative stress are pressing the industry towards cleaner procedures, cultivating collaboration between article source producers and ecological organizations. As these fads merge, the future of Aluminum factories will likely be identified by a commitment to quality, sustainability, and performance, ensuring their significance in an affordable market.

Often Asked Inquiries

What Are the Environmental Influences of Aluminum Foundries?

Aluminum foundries add to ecological effects with power intake, greenhouse gas discharges, and potential air and water pollution. Additionally, mining bauxite for Aluminum can cause habitat damage and dirt degradation, impacting local ecosystems.

How Do Shops Make Certain Employee Security During Production?

Shops apply rigorous safety procedures, including protective tools, ventilation systems, and normal training. They conduct threat assessments and preserve safety and security standards to lessen dangers, making sure a much safer working environment for staff members throughout the manufacturing procedure.What Certifications Should a Light Weight Aluminum Foundry Have?

An aluminum Foundry need to possess accreditations such as ISO 9001 for quality monitoring, ISO 14001 for environmental administration, and OSHA conformity for safety and security criteria. These certifications ensure adherence to market guidelines and commitment to high quality and security methods.Exactly How Does Aluminum Recycling Affect Foundry Workflow?

Aluminum recycling substantially enhances Foundry procedures by offering a cost-efficient basic material source, decreasing power consumption, and decreasing environmental impact - Wisconsin Aluminum Foundry. It also motivates lasting methods, allowing shops to keep competitiveness in a rapidly developing marketWhat Prevail Defects in Aluminum Castings?

Typical defects in Aluminum spreadings include porosity, shrinking, inclusions, and surface area blemishes. These concerns can occur from inappropriate mold layout, poor putting methods, or contamination during the melting and casting procedures, impacting overall product top quality.

Report this wiki page